Manufacturing Processes

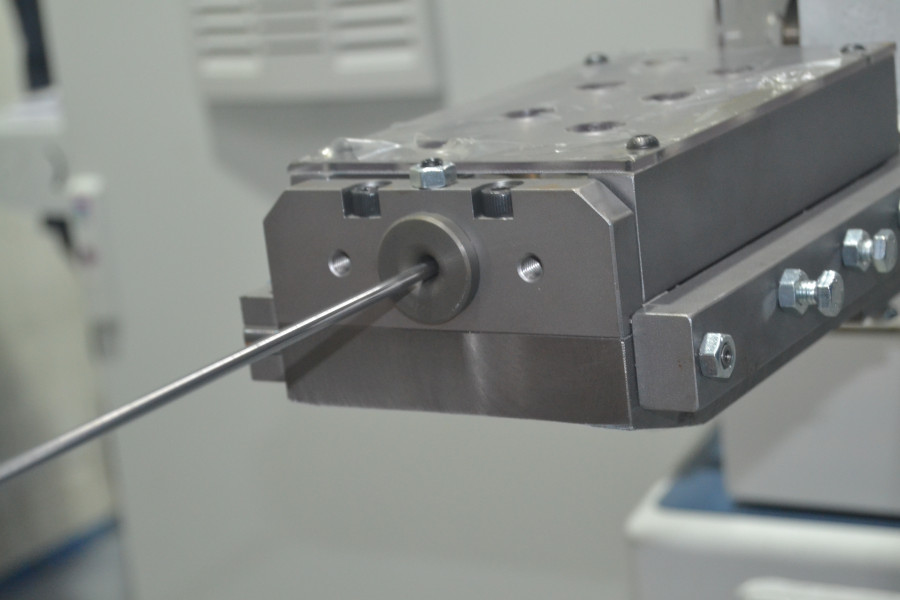

injection-molding

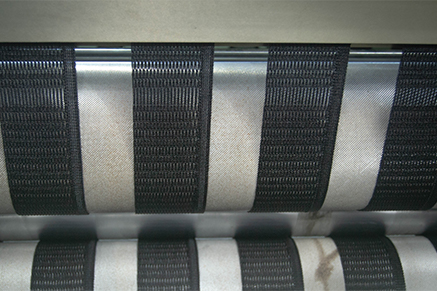

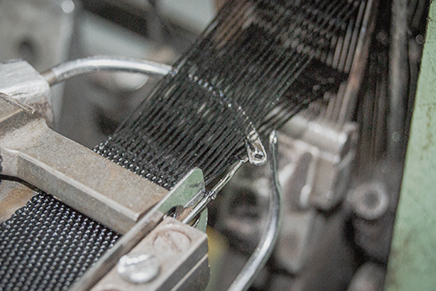

Knitting, Braiding, Weaving

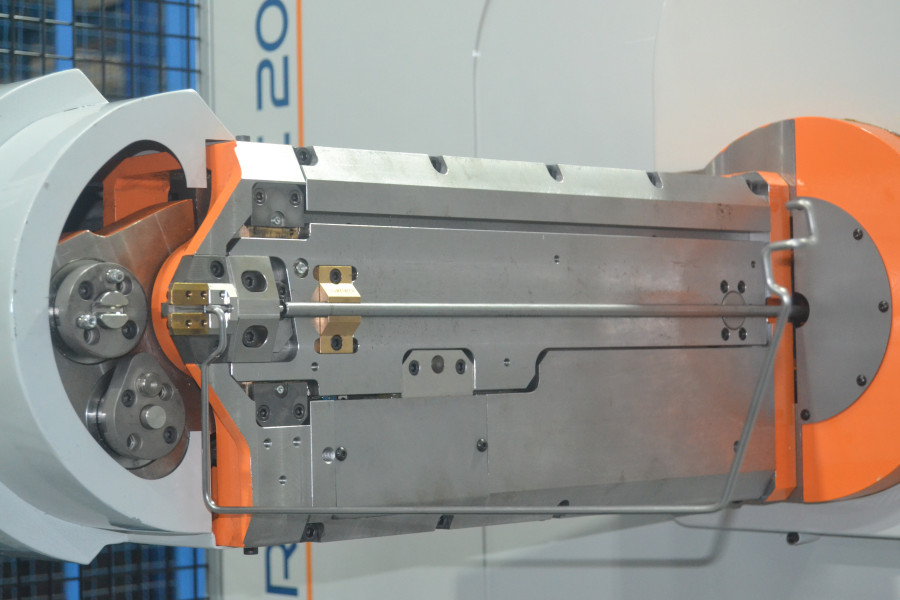

Polydesign has made a name in the global net market thanks to its 20 years of experience in designing and manufacturing netting products from different materials, including multifilament polypropylene, nylon, polyester yarns. Our vertical integration encompasses knitting, weaving, braiding, lycra/rubber covering, as well as wire bending, injection molding, and assembly, enabling us to precisely design nets responding to the highest expectations in terms of robustness and durability.

Assembly

Polydesign’s assembly know-how evolution accompanied its growth. We deliver a wide selection of assembly processes according to our clients’ needs and demands.

foam-in-place